OVERVIEW

GSE is an Indian based manufacturer of engineered systems and solutions. The Group is a leading supplier of systems and components for the off-highway market, tractor spare parts and accessories and hydraulic damper parts. GSE was established in 2016 to specialise in the manufacturing of train Bogie Parts.

GSE is equipped with the latest manufacturing and testing equipment with a workforce of 25+ in all. GSE an established unit, was started Under the guidance of Aditya Kumar Tyagi, who is having rich experience in the industry to meet the requirements of Off-highway markets, hydraulic damper parts, Agriculture Implements and other Engineering Goods.

BUSINESS AREAS

GS ENTERPRISE HAS A DIVERSIFIED BUSINESS PORTFOLIO CATERING TO MULTIPLE INDUSTRIES

Construction and Forestry

GSE is a supplier for precision machined parts (PMP) and Hydraulic Cylinder Parts to the mobile equipment market and in particular to the construction market. Read More

Railway

GS ENTERPRISES is the leading manufacturer of bogie parts specialization in hydraulic damper parts. We are the leading railway parts manufacturer for safety critical components for both conventional and LHB coaches Read MoreWhy Choose Us

Precision Machined Parts with Expert Consultation and a Broad, Durable Product Range

Operational Excellence

Our highly skilled and enthusiastic staff is capable of fabricating precision machined parts with excellent finish, defect-free quality, and corrosion-resistant metal.

Broad Product Range

We provide durable, reliable precision parts, including connectors, auto components, screws, shafts, bushings, and custom pieces.

Expert Consultation

Through our special consultation on manufacturability improvements as well as product design, we help our clients ensure the lowest possible cost for their projects.Our facilities

GS Enterprises offers a wide range of services tailored to meet the needs of their customers

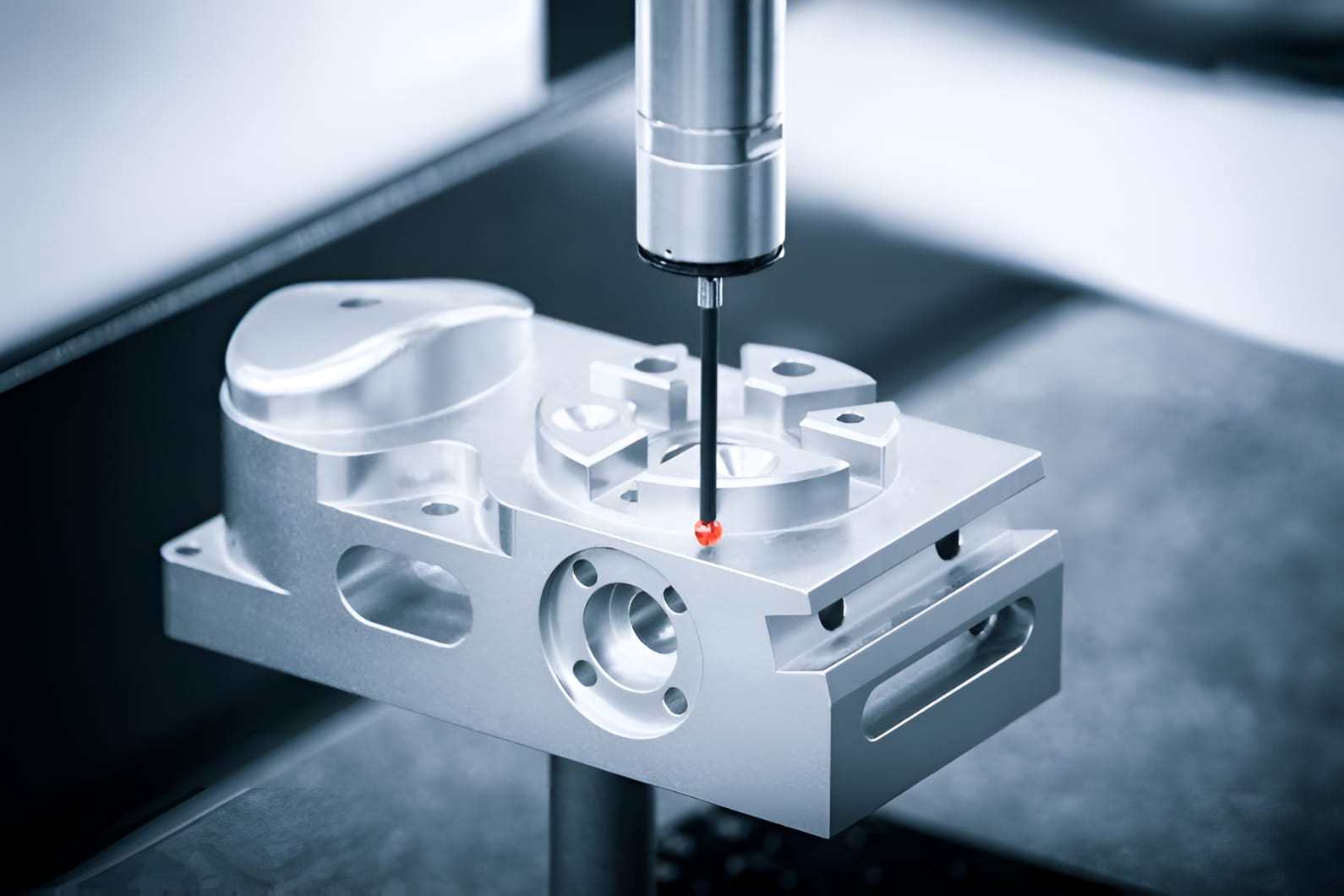

MACHINING

GS ENTERPRISES is equipped with a wide variety of CNC & Conventional Machining equipment to manufacture high precision components with reduced cycle time to ensure the right quality and quantity for its customers.

FORGING

The forging division of the GS ENTERPRISES in India is located in the Ludhiana region. The forging facility has integrated 3-D CAD & CAM application for product and tool design. The facility is linked to the tool room and machining centers for high-speed cutting of dies.

SURFACE FINISH

GS ENTERPRISES has various surface finishing technologies matching up with diverse customer & product requirements. The group has expertise in the surface finish processes and has built redundancies by having similar processes.

QUALITY AND TESTING

The highest level of quality standards is maintained in all of the processes and procedures. Utmost importance is given on maintaining the optimum level of quality at all levels from raw material testing, patrol and stage inspection to final inspection.

LOGISTICS

Logistics services can help businesses streamline operations and improve efficiency by optimizing transportation routes and delivery times. GS ENTERPRISES regulate inventory levels and assess demand and supply.